Copper plating and silver plating filler

At Yasuda Chemicals, we contribute to our own processing technologies in gold plating, such as silver and copper.

Copper plating and silver plating filler

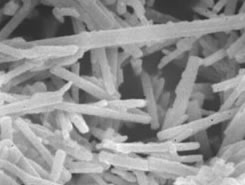

The silver plating technology (conductive filler) we handle is a highly functional, highly conductive material that can accommodate miniaturization and weight reduction in the electronics field.

Characteristics

- [High conductivity]

- Compared with the conventional Ag flour and Ag flakes, a lower amount (1/2) of this product provides equivalent or better conductivity.

- [Excellent ink-paste properties]

- Provides a uniform and stable conductive film and paste with excellent dispersibility and difficulty sedimenting.

- [Excellent processivity]

- Material with excellent weather and chemical resistance, low hardness, and high dispersibility.

- [Excellent fine pattern characteristics]

- Low sag allows for finer pitch.

- [Low linear inflation coefficient]

- Has a linear expansion coefficient close to that of ceramics, and is excellent in crack prevention and adhesion.

Applications: Conductive paste, conductive glue, electromagnetic wave shielding paint

Application of silver plating conductive filler

- Conductive paste

- Stable conductivity is volatilized with less added amount than Ag flour ⇒ Low cost

- Small specific gravity makes sedimentation superior ⇒ Difficult to hard caking

- Low sagging ⇒ Good fine pattern characteristics

- Core material is ceramic ⇒ Linear expansion coefficient is small

- Conductive adhesive (Pb hand substitute)

- Reinforcement Effect of Fiber Shape ⇒ Enhancement of Bond Strength

- Random variance ⇒ Resistance equivalent to X, Y, and Z axes

Flow from request to product delivery

Here, we present the flow from the request to delivery of the product for plating.

- Please

- Inquire via telephone or website first.

- Meeting

- Conduct discussions of product specks, etc. regarding copper and silver plating for substances.

- Prototype

- Plat copper or silver on designated substances and make prototypes.

- Sample evaluation

- The prototype is sent to the customer, and the prototype is used to manufacture and evaluate the product.

- Mass production trial

- We will conduct mass production trial in order to confirm the variation, etc., in the specifications between product lots.

- Product delivery

- Production is carried out under a strict control system and delivered.